Stock Code: 831045

Industrial Automation & Intelligence Solutions

Automatic orbital welding is to use mechanical and electrical methods to drive the welding equipment to move the welding gun around the pipe wall along the weld when the pipeline is relatively fixed, thereby realizing automatic welding.

Turnkey and customized solutions that deliver unmatched speed, accuracy, reliability and versatility for customers spanning diverse industries. We design and build specific mechanical hardware and electrical control systems for a wide range of customer applications. That process include:industrial planning,mechanical electrical design,simulation,manufacturing, detection, robot debugging, field setting and after-sale service.

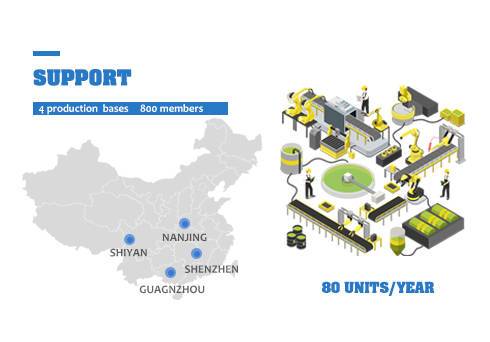

The company owns 41 patents and 11 software copyright register certificates have been hold by the company, and it has also been appraised as the National Hi-tech Enterprise, Henan Engineering Test Automation welding supporting unit, Post-doctoral research and development base, OTC Welding Robot Henan Technology Center,Vice President Unit of Henan Robot Industry Alliance, Henan key industrial products compliance record company, Zhengzhou intelligent welding automation equipment engineering technology research center, and Zhengzhou intelligence Welding Equipment Engineering Research Center. At the same time, we actively deploy the international market. Our products have been exported to more than 40 countries and regions, providing industrial upgrading services to more than 200 international companies around the world that include automotive, chemical, the animal husbandry, chemical, the food processing, medical and other fields. What is the accomplishment that we are most proud of is the team has designed 8 “first sets intelligent production lines” independently in different fields in China, such as chemical industry, food industry, and animal husbandry industry etc. Zhengzhou kehui Technology has over 300 welding experts in 4 states of China (headquartered in Zhengzhou)and then work with customers to determine the best combination of components for their specific needs, from analyzing parts and processes. Amount them, 80% of the employees have more than 8 years with rich design experience. What is on the main line for body-in-white welding, body parts and parts, robot welding systems, body parts welding fixtures, car longitudinal beams, Chassis, instrument skeleton welding fixture production line, car seat welding, assembly, commissioning, testing production line, welding equipment and other non-standard equipment. With our tech-support, you can depend on unmatched quality, integrity and time service, including 24/7 technical phone support associates with an average of 23 years of robot experience. By allowing our applications engineers to serve as program manager once an order is taken, there is continuity from the time the job is quoted to final production. When designing your project, we take to heart your goals and specification, and address in detail how we plan to achieve them. And given the opportunity, we can meet almost any budget and deliver a piece of equipment that meets or exceeds the expectations of your team.

We value your message!

Please fill the below, We will customized the solution to your needs.