Stock Code: 831045

Industrial Automation & Intelligence Solutions

How we can help our customers:

Welding is an important process in metal structure welding industry which needs high skills and precision, but skilled welding workers become more and more scare due to poor working environments. Therefore, more and more manufacturing plants turn toward automatic production line to prevent downtime and boost productivity.

KETHUI has successful experience on auto production line for metal manufacturing, which helps customers improve welding quality greatly and increase the production efficiency by 4-5 times.

All production lines can be customized according to the actual situation of customers.

Brief Introduction:

The line was mainly composed of six systems including:

Metal parts pretreatment system that cut or bend items to required size and shape before welding;

Automatic loading and unloading system to maintain maximum speed;

Flexible Robotic welding system allow the same robot to weld multiple parts;

Precise positioning and linear transfer system drastically reduced transfer time with high accuracy

Visible master control system that can controlled all motion precisely

Safety and environmental protection system to create safe and green workshop.

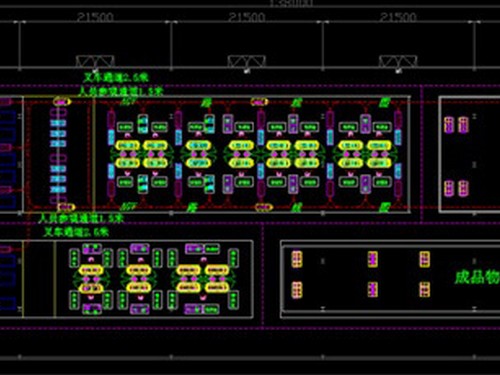

Layout Plan:

Advantage:

1. High equipment utilization allow for lower facility investment cost;

2. Low labor intensity and high efficiency maximize your return in investment;

3. High product qualification rate and consistency ensures cost effective investment;

4. High degree of intelligent logistics automation minimize production break.

5. High degree of information management ensures high accuracy and speed;

6. Highly practical and beautiful line body to improve corporate identity;

7. Convenient and quick product replacement ensures longer service life.

Why choose us?

KETHUI TECHNOLOGY has plentiful successful projects solutions on automatic production lines for all kinds of metal structure welding including:

Automatic production line for livestock equipment

Automatic production line for pressure vessel as boiler, heat exchanger

Automatic production line for metal furniture

Automatic production line for vehicle frame

Automatic production line for electric equipment as power cabin, transformer

Automatic production line for auto parts etc.

All production lines can be customized according to the actual situation of customers.

Key Benefits:

With more than 24 years of experience in design, manufacturing, and service, Kehui Technology can formulate excellent intelligent overall solutions for each customer, and achieve a perfect one stop service from design, selection, production, installation, debugging to after-sales, truly realizing turnkey project-style cooperation.

All the turnkey systems ensure you invest in most flexible facilities with high quality and max production.

Contact us now to discuss your needs.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.