Stock Code: 831045

Industrial Automation & Intelligence Solutions

1. The core components are imported from Japan, with excellent technical performance:

Equipped with Japan Yaskawa welding power supply, low welding spatter welding machine, with pulse welding and short-circuit welding; welding gun with Japan East gold welding torch, excellent performance; welding gun sensing using 360 °anti-collision device to avoid welding collision Damage to the robot body.

2. 360 °all-round welding, taking into account quality and aesthetics:

The three-axis servo flip positioner can be used for 360°free flipping and positioning, and robot for all-round welding. The AC servo motor drives the positioning accurately, the clamping is firm, the starting operation is stable, and the parking position is accurate. Base of the positioner is made from high-quality steel profiles and welded. After annealing, the quality and accuracy are reliable.

3. The structure is simple and easy to operate, efficient and stable:

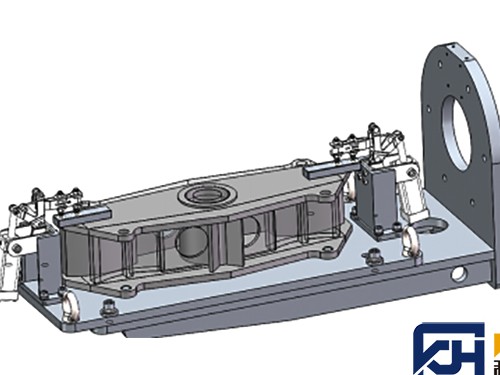

The fixtures include three types: balance tooling, front bracket tooling and light front bracket tooling. The tooling fixtures are designed with automatic clamping positioning to enable information interaction with the handling robot. The utility model has the advantages of simple structure, convenient operation, high efficiency of the pair, and firm and stable clamping force.

4. Germany automatic clearing wire cutter, long service life:

The German Binzel clear gun wire cutter TCS is used. The automatic clearing and cutting device consists of a clearing gun station, a wire cutting mechanism and a spray silicone oil unit. The clearing gun station is precise and efficient, the wire cutting mechanism is of good quality, and the spray silicone oil device adopts double nozzle cross jetting, which effectively reduces the number of cleanings and has a long service life.

1.Fixtures

the fixtures adopts automatic clamping and positioning, ability to match with handling robot information. Simple structure, convenient operation, high efficiency of assembly, and stable clamping force.

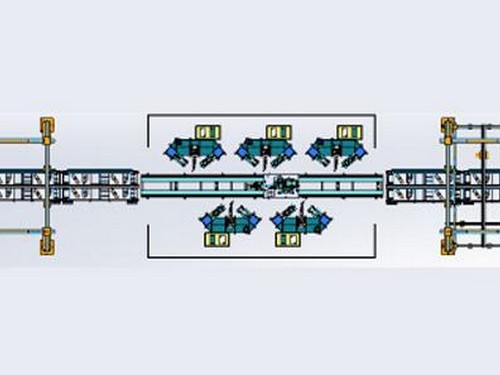

2.The times speed conveying line

Adopting double-layer times speed conveying, which is divided into upper and lower layers, and the self-returning is formed. The workpiece is positioned on the conveying chain plate by the location pin, and a secondary positioning mechanism is arranged in the transfer robot connection area to automatically complete the precise positioning of the chain plate.

3.Robot slide platform

Driven by servo motor + precision planetary reducer, free programming. It adopts domestic famous brand reducer, guide rail, slider, rack and pinion, which has high walking precision, meets welding requirements and has long service life.

4.Conveying line of robotic loading and unloading line

Mainly includes loading and unloading robot, robot control cabinet, robot teaching pendant, robot slide platform, compatibility automatic gripper, times speed chain logistics line, plate chain type of logistics line and control system.

5.The control electric of welding production line

The programmable program control system is adopted, and the main control part is controlled by PLC system. With “manual” and “automatic” optional features,

With: reservation, power on/off and indication, emergency stop button, with mechanical anti-collision, servo anti-collision, power status detection, interference field inspection and other functions.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.