Stock Code: 831045

Industrial Automation & Intelligence Solutions

Advantage:

1. Integrate inventory in an all-round way and promote reengineering of supply chain processes.

2. Deeply integrate warehousing and logistics resources to provide support for e-commerce development.

3. Build smart warehouse logistics and gradually realize Internetization.

4. The information platform is interconnected and facilitates the construction of the city’s common distribution system.

5. Excavate the value of inventory and further regulate the management of inventory.

6. Innovative application of green technology, leading the continuous transformation and upgrading of the warehousing industry.

7. Wild application:

a) Application types: E-commerce, manufacturing, trade circulation, tripartite warehousing.

b) Application industry: Home appliance industry, clothing industry, hardware machinery, automobile manufacturing, agricultural production, fast-moving industry, publishing industry

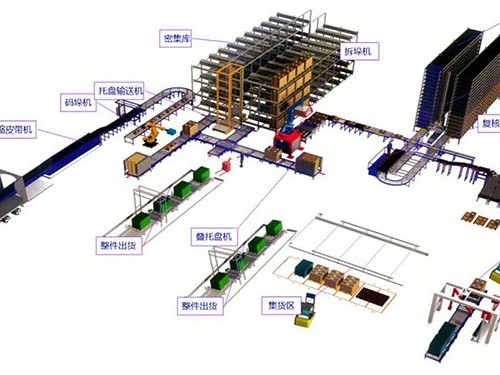

Plant Components:

1. Computer Management System:

Establish a warehouse database, record the inventory situation in real time, issue instructions according to the needs, and guide each part of the intelligent storage system to make corresponding actions to realize the warehousing function.

2. stacking system:

Goods can be transported from one location to a designated location by manual, semi-automatic or fully automated operation. It consists of a frame (upper beam, lower beam, column), horizontal running mechanism, lifting mechanism, cargo bed, fork and electrical control system.

3. three-dimensional warehouse:

The three-dimensional warehouse is the main equipment for storing goods in the high-bay storage area. It requires sufficient strength and rigidity and overall stability, and the dimensional requirements are high precision and meet the seismic requirements. The utility model adopts an adjustable beam combined shelf, which is composed of a shelf piece, a cargo beam and a reinforcing support member, and is plugged and connected, and the height is adjustable, and the height of the cargo space can be adjusted when necessary. It is convenient to transport and install. The combined racks mainly meet the needs of long-term automatic operation of the vertical storage equipment.

4. AGV system:

Automated Guided Vehicle (AGV) refers to a transport vehicle equipped with electromagnetic or optical automatic guiding devices that can travel along a prescribed guiding path. It has safety protection and various transfer functions. Through the computer to control its route and behavior, or use the electromagnetic path-following system to set up its route, the electromagnetic track is glued to the floor, and the unmanned vehicle moves according to the information brought by the electromagnetic track.

5. Conveying equipment:

Conveying equipment includes chain conveyors, roller conveyors, transfer machines, hoists, AGV, RGV, etc., which are widely used in production logistics, such as workshop conveyor lines, online packaging lines, and automobile assembly lines;

In the automated three-dimensional warehouse system, the conveying system is a channel and bridge connecting the production site, the working area and the storage area, and has the advantages of high automation, high continuous operation efficiency, low maintenance cost, convenience and quickness.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.