Stock Code: 831045

Industrial Automation & Intelligence Solutions

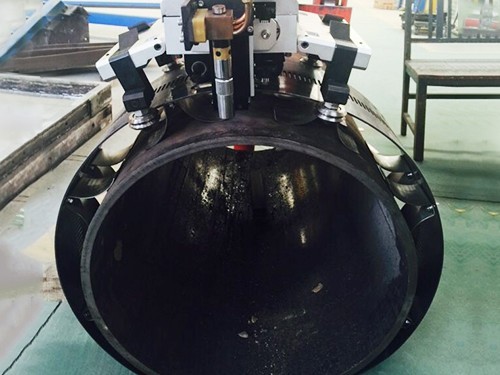

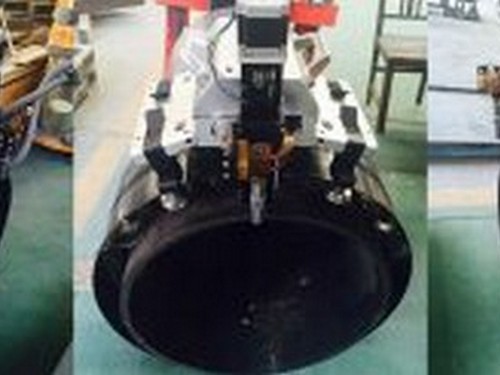

1.High efficiency

Pipe line in all positions of the automatic welding machine, making a great advance of the limitation of the orbit, saving the cost of installation of the orbit and the consumption of time.

2.Automatic welding

The use of automatic welding instead of manual welding, which is 3 times faster than traditional manual welding, greatly improved not only the welding efficiency, but also the quality of the welding, also saving labor costs.

3.High accuracy rate

The qualified welding inspection rate of more than 98%, will guarantee the quality of the welding.

4.High cost performance

Achieved a technological innovation without orbit, high quality, low price, highly profitable.

Welding power source:

Finland Kemppi welding power supply, Welding carbon dioxide protection

Welding control system:

Products The company’s patented technology products, digital remote control.

You can perform the control of the movement of the welding cart, the debugging of the welding gun up and down, the purging of the left and right welding gun, the turning of the welding gun to the left and right, the welding gun delay to the left and right, the voltage of the welding current, etc.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.