Stock Code: 831045

Industrial Automation & Intelligence Solutions

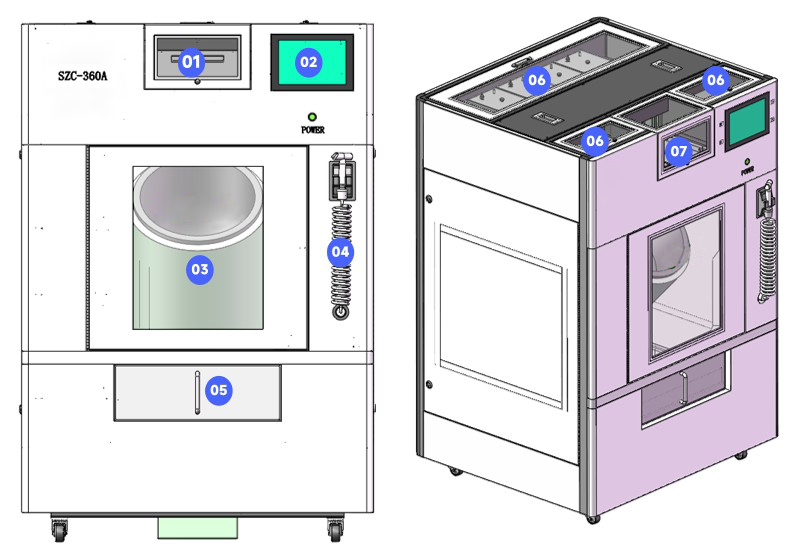

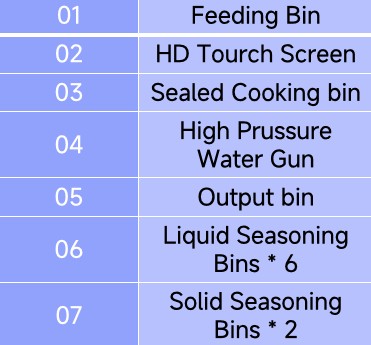

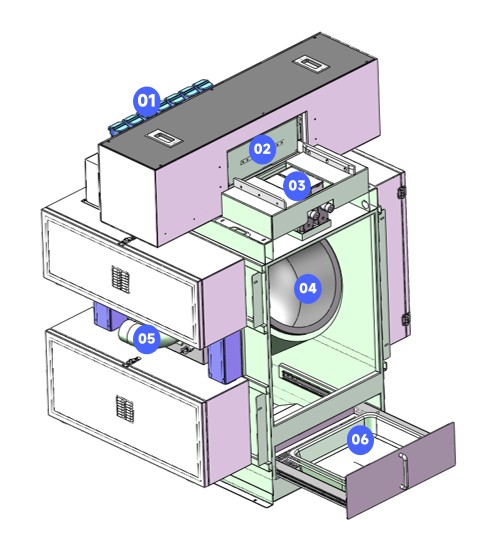

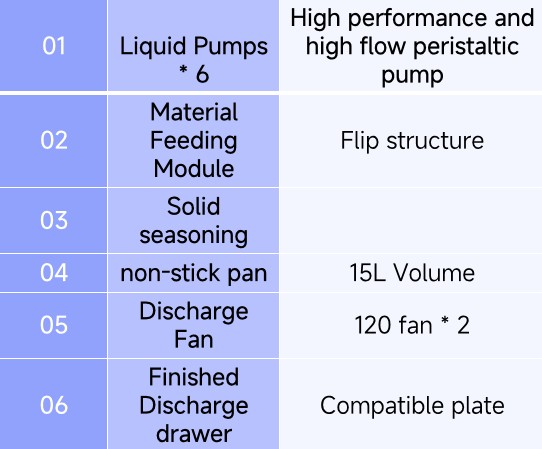

SZC-360A Strcture Chart Front & Top:

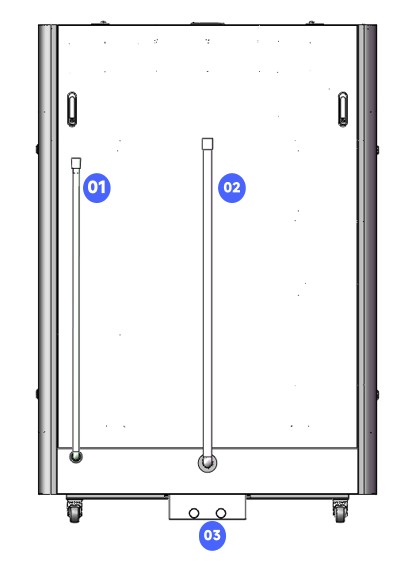

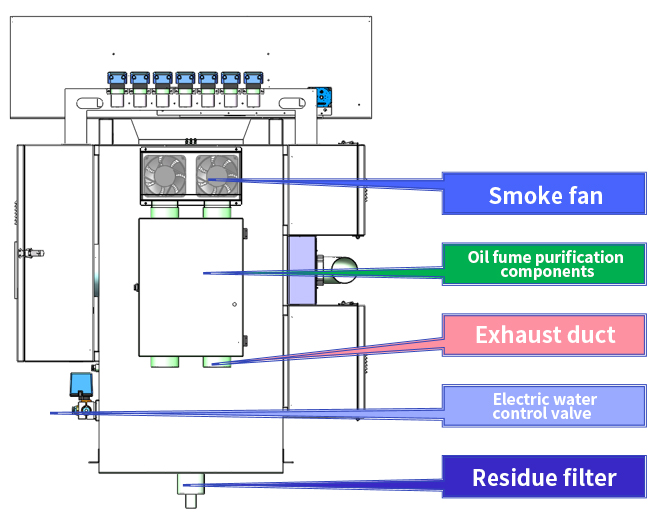

Back Display:

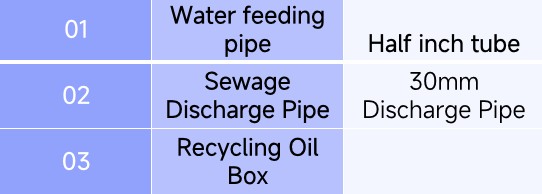

Internal Display:

Advantages:

Kitchen management

Provide meals all day and all the time, and one-button cooking without interference, and one kitchen helper can control 3-5 machines, greatly reducing operating costs

Taste of dishes

Digital chef technology, touch screen controls the time, sequence, heat, and amount of materials, accurate to 0.1 seconds/0.1 grams, and chefs from all over the world gather at their fingertips to perfectly replicate the level of state banquet masters.

Taste of dishes

Digital chef technology, touch screen controls the time, sequence, heat, and amount of materials, accurate to 0.1 seconds/0.1 grams, and chefs from all over the world gather at their fingertips to perfectly replicate the level of state banquet masters.

Oil fume purification

When cooking oil is heated above 200℃, acrolein, the main component of oil fume, is generated. It has a strong pungent taste and is a strong irritant to the mucous membranes of the nose, eyes, and throat, which can cause respiratory diseases such as rhinitis, pharyngitis, and tracheitis.

When oil fume passes through a high-voltage electric field, the oil fume molecules are ionized and charged. Under the action of the electric field force, the charged oil fume molecules are adsorbed onto the dust collecting plate with the opposite charge, thereby achieving oil fume purification.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.