Stock Code: 831045

Industrial Automation & Intelligence Solutions

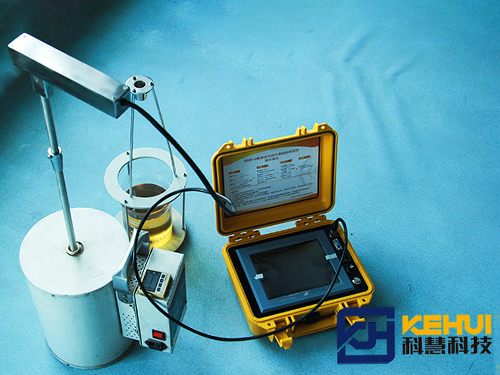

Three major advantages of IVF SmartQuench cooling characteristics tester

1. Handheld test and data receiver

• The handheld test and data receiver are linked and powered by batteries.

• It can store six sets of measurement data at the same time.

• The user can set the measurement time, frequency and measurement mode through the three buttons on the data receiver, including the start temperature of automatic recording and the calibration of the test carbon rod.

• Because the handheld test and data receiver are small and light, multiple handheld test and data receivers can be used to measure several sets of data at the same time, and then measure the quenching media of several quench tanks at the same time.

• If you want to test the cooling curve of the actual workpiece during quenching, you can use a single thermocouple to connect to the data receiver.

2. Wireless Bluetooth data transmission system

The IVF intelligent quenching medium cooling characteristics detector uses wireless Bluetooth data transmission, which makes testing at any position in the quenching tank more convenient, improves work efficiency, and reduces measurement errors caused by poor grounding of the test probe.

• Your PC can be placed anywhere convenient for you, 10-30mm away from the quenching tank.

• The current probe temperature can be displayed on your PC

• Parameter settings can be performed on your PC, and data records can be displayed on your PC and can be downloaded.

3. Powerful cooling curve analysis software

IVF has designed and arranged powerful cooling curve analysis software for the intelligent quenching medium cooling characteristics detector. It is used to process the large amount of test data recorded.

• Data input, using high-performance data filtering to suppress noise in the test data.

• Data analysis can directly draw the temperature-time cooling process curve and cooling rate-temperature cooling characteristic curve of the probe in the measured medium.

• The bar chart in the data analysis chart area can display the maximum cooling rate for each line. Other parameters, such as the cooling time or cooling rate corresponding to a certain temperature, can be displayed on the bar chart.

• Powerful formula editor, such as automatic calculation of quenching hardness (HP). You can also calculate the quenching hardness under specific working and specific quenching conditions according to the editable formula.

• Powerful database selector, which can optimize the selection of qualified quenching media or quenching conditions stored in the database.

It is suitable for factories, laboratories, scientific research institutions and colleges and universities to engage in the selection, development, and co-construction of quenching quality control of quenching or coolants, as well as the optimization of quenching process parameters.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.