Stock Code: 831045

Industrial Automation & Intelligence Solutions

1.High degree of automation, good flexibility, large memory capacity, simple teaching:

Various positioning workpieces or clamping mechanisms can be easily installed, it has linkage control interface and corresponding self-protection function, centralized control and coordination work. It can be quickly adjusted according to changes in manufacturing tasks and production environment, adapting to small and medium batches and multiple varieties.

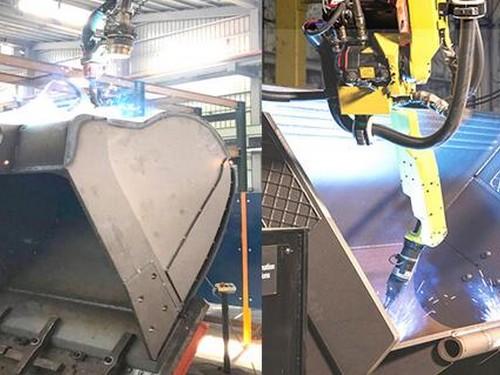

2.Carrying welding tongs with built-in transformer, high efficiency and stable welding quality:

The welding running speed can be adjusted, has good structural rigidity, effectively ensures rapid welding, and utilizes the advantage of fast servo rotation speed, which is more conducive to cross welding, and significantly improves the welding quality and efficiency of the workpiece. The positioning accuracy is high (±0.25mm) to ensure the welding quality, the spot welding speed has been matched by the production line, and the full reliability is good.

3.Significantly improve production efficiency and significant economic benefits:

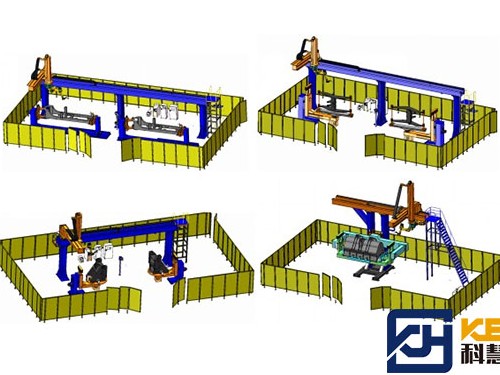

The whole system adopts double-station welding robot. Welding, disassembly, clamping and handling can be completed independently without mutual interference. It can realize all-weather uninterrupted welding, greatly improve production efficiency and significantly improve economic benefits. Quickly complete multi-point positioning with small pitch, which can achieve continuous “unmanned production” for 24 hours.

4. The installation area is small, the work space is large:

Improve equipment utilization, less equipment and floor space. According to the matching of welding operations, the processing of required parts can be arranged in time, thereby reducing the inventory of blanks and products, thereby reducing the corresponding funds and venues.

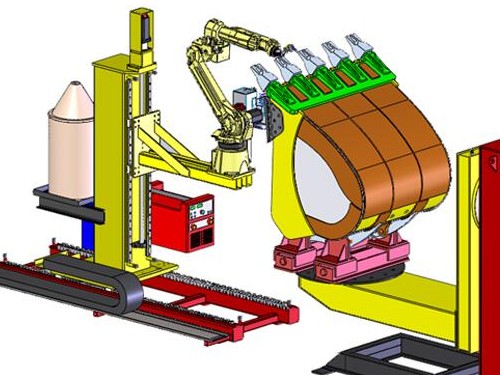

It consists of welding robot system, servo positioner, system controller, touch screen, welding controller, welding gun unit (welding gun and transformer), traveling mechanism and welding auxiliary equipment (cold power supply, compressed air unit) , safety light curtain, cooling water unit, electrode dressing device, clearing gun wire cutter, lifting blinds).

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.