Stock Code: 831045

Industrial Automation & Intelligence Solutions

Overview Product

New Product

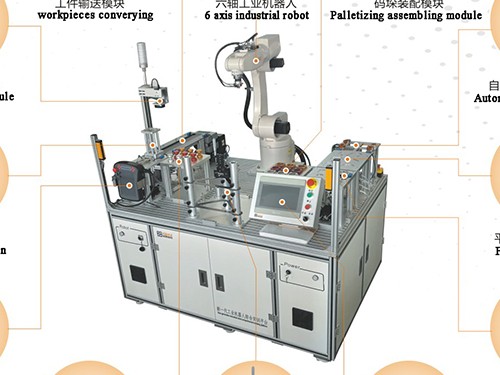

The new generation of industrial robotics comprehensive training platform is a new product specially developed by Techwise to meet the education, teaching, practical training and competition needs of the current industrial robotics, intelligent manufacturing and industrial Internet professions, and is fully aligned with the new occupational standards of the Ministry of Human Resources and Social Security.

It is a new product that is fully aligned with the new vocational standards of the Ministry of Human Resources and Social Security.

Flexible configuration

The product takes the operation, operation and maintenance of industrial robots, Internet of things, cloud platform training and competition as the core, and adopts modular design, which can be combined and configured flexibly according to different needs of teaching, experiment, training and competition and different levels of technical depth.

Powerful functions

It can carry out practical training on common processes such as robot palletizing, logistics, assembly and welding; it can carry out operational practical training on mechanical assembly and disassembly, electrical line assembly and disassembly, PLC programming and debugging, robot vision application and programming, industrial robot programming and debugging, industrial robot performance testing, system operation and maintenance; through IOT and cloud platform, big data predictive maintenance platform, it can carry out remote fault setting, remote fault recovery and It is suitable for industrial robot operator competition, industrial robot operator competition and IOT/Cloud platform competition.

Wide range of adaptability

Rich optional, suitable for all kinds of vocational colleges, applied undergraduate and technical schools and other different levels of practical training teaching needs, and can be aimed at enterprise automation technicians for engineering training and skills competition.

Product innovation points

1. The safety of teaching equipment is of paramount importance. The equipment adopts three levels of safety protection measures to provide important security; the addition of grating identification, multi-point set emergency stop switch, effectively improve the emergency response capability.

2. Vision system: hardware selects industrial-grade camera + embedded vision controller; software provides rich function modules, convenient configuration, simple and practical; meanwhile, it can be designed from code level according to special process requirements to realize personalized advanced algorithm.

3. The process module can be flexibly grouped at different levels according to the depth of technology. For example, through visual recognition of the color and type of workpiece, fixed-point gripping, palletizing or assembling; through visual recognition of the position of the workpiece, dynamic gripping, palletizing or assembling; secondary positioning of the workpiece, precise assembly; welding process can choose plane weld simulation, or space curve weld simulation, and can also implement a variety of transport bar technology to brilliantly display the pattern of weld traces.

4. The first welding wire tray/wire feeder/simulation welder controller/weld filling physical simulation module, which provides an intuitive, environmentally friendly and fitting practical training scenario for robot welding teaching.

5.Robot typical joint detachable training module is uniquely designed to facilitate mechanical fault setting, fault analysis and dynamic detection.

6. The IOT/Cloud Platform/Predictive Maintenance module can perform remote diagnosis and predictive maintenance of industrial robots through real-time data collection, and remote electrical fault setting and fault recovery, adapting to the needs of industrial robot competitions.

7. The industrial robot performance testing is carried out in full accordance with the international standard (ISO9283) and the method recommended by GB/T 12642, and the positional accuracy and positional repeatability of the whole industrial robot can be easily tested.

8. The platform can be configured into “industrial robot operator training platform”, “industrial robot operator training platform”, “Internet of things/cloud platform/big data predictive maintenance platform” and other functional versions according to user needs. The platform can be configured into different functional versions such as “industrial robot operator training platform”, “industrial robot operator training platform”, “IOT/Cloud platform/Big Data predictive maintenance platform”, etc.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.