Stock Code: 831045

Industrial Automation & Intelligence Solutions

1.Easy operation, 24h continuous production without senior welders

The station adopts modular design. Various sets of parameters can be set for different welding process. The operator just needs to choose the suitable set of parameters. Robot can quickly finish welding of straight and orbital seams. It can continuously work for 24hours. No senior welders needed.

2.Coordinated servo positioner and weld gun, uniform weld quality

Coordinated reversal of the servo positioner and posture change of the robot gun can realize the welding of straight lines, arcs and other complex weld seams. The weld joints are regular and flat. The welding wave (texture) is uniform in thickness. It has excellent surfacing layers. Can be used directly after welding without further processing.

3.Adjustable weld speed, stable and uniform weld quality.

The station adopts enhanced servo control system. Its adjustable welding speed can decrease work piece deformation. Automatic wire feeding device, wire cutting and cleaning system ensure stable and uniform welding quality. Problems such as wire clot, air hole and slag on welding surface are effectively avoided.

4.First-class servo and motion control system, strong adaptability

The station uses modular design. Controller and sensor are separately displayed. Compact sensor structure is suitable for narrow space. Special cooling system allows it to work in harsh environment. Weldable material range and workpiece size are expanded by robot walking track and positioner. It reduces further cost on the equipment.

5.Provides turnkey projects, remote and on-site technical service

KEHUI is a three board listed company, we have a complete after-sales system. Equipment parts are standardized and modular as much as possible. Our KEHUI Remote and On-site Service can respond to your request in the first time and provides technical support in analyzing and rectifying faults and servicing your system.

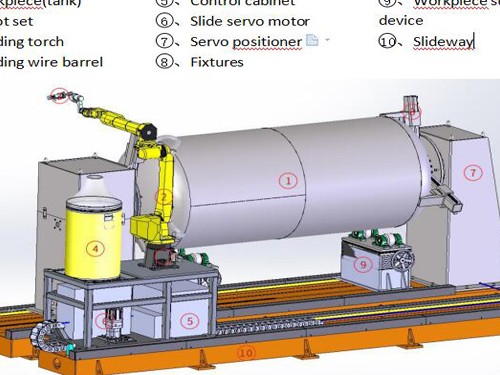

The tank welding station consists of M-10iA/8L robot, Artsen CM 500R welding power supply, customized welding station, UNI300 laser tracking, and customized electrical&gas control system.

No Any Post.

According to user needs, we providecomplete production line design. including: industrial planning, electromechanical design, simulation.

Provide a complete production lineelectrical control system and software.

Assign engineers to perform on-siteinstallation and commissioning, andtrain operators.

Provide all-round product after-salesservice and solve technical problems for customers in a timely manner.

We value your message!

Please fill the below, We will customized the solution to your needs.